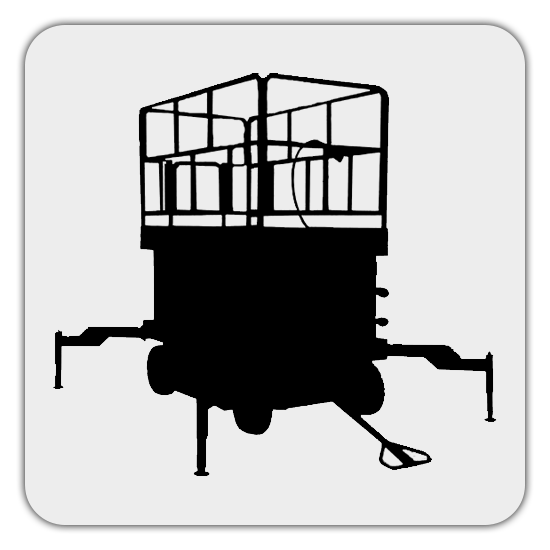

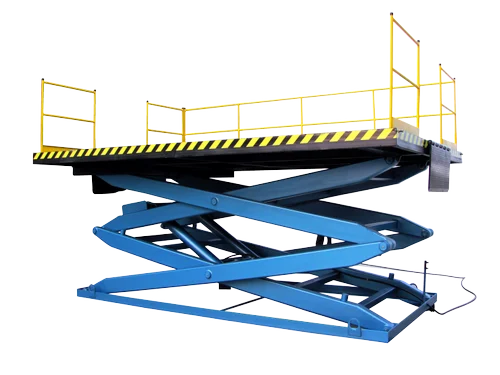

If scissor lifter table is needed more than one places or it needs to be moved and parked at some other place after work, then Movable Scissor Lift Table can full-fill your needs.

Structure: The Scissor lift table’s main part is scissor arms which are made from MS Pipes (Grade- YST210/YST240/YST310). The top platform and Bottom frame are made from MS Channel, Sheet, Angles, and Pipes. Scissor Joining Pins are processed through carburizing, hardening, and grinding. These processes make them durable for life. Gunmetal Bushes are used at scissor joints for smooth and silent operation. Grease nipples are also provided on pins for smoothening the operation.

Hydraulic Cylinders: Hydraulic Cylinders are inclined mounted with appropriate rod, bore and stroke size as per capacity requirements. High strength steel piston rod is precision ground and hard chrome plated to ensure anti-corrosive and durability of seal. Seamless Honed Tubes (Steel) to a micro-finish are used to which ensures long piston seal life and prevent failure of the cylinder.

Wheels: Size of the wheels will be chosen as per the capacity requirements and Material of wheels are chosen as per the application and environmental conditions.

Handle: One U-shape Handle is provided to push, pull and turn the table. Handle can be removable type or fixed type as per user requirement.

Railing: Two, three or four side railings are provided as per user requirements.

Paint: Entire structure shall be powder coated or PU finish painted.

Power Pack Unit: Manual Hand Pump / AC Power Pack or DC Power pack As per Requirement.

Features

- Movable scissor lift tables are manually moved and lifted by a Hand Pump / Power Pack. The operation is very easy and smooth.

- It has easy maintenance and low running cost.

- A Brake is provided in Caster wheels or separately to lock the movement while lifting, loading or unloading.

- It is specifically designed and built as per customer’s requirement.

Reviews

There are no reviews yet.